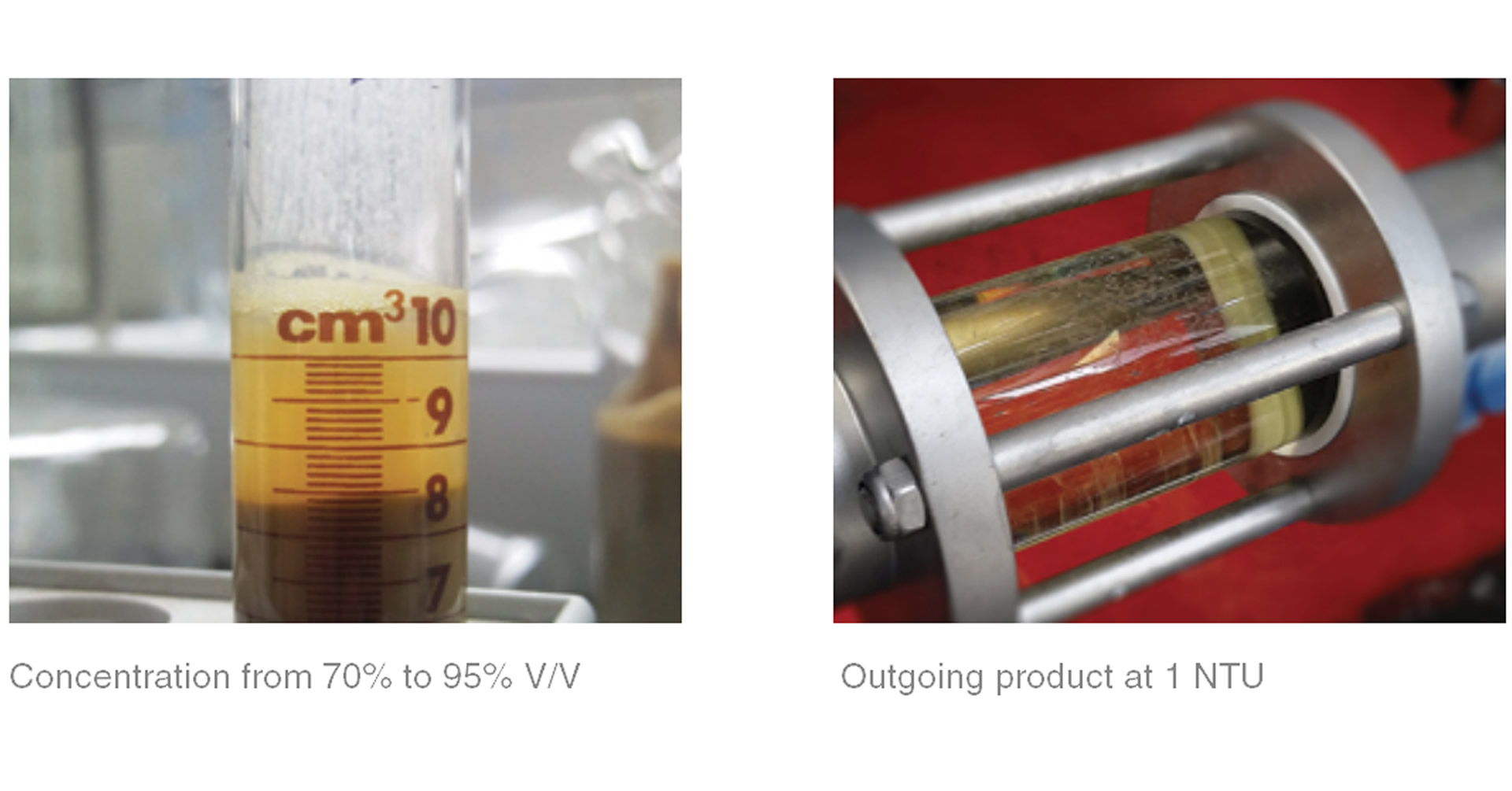

VLS Technologies was awarded the New Technology award at SIMEI 2015 for “Lees-stop”, a cross-flow solution for the filtration of products with high solids content (replacing traditional polymeric membranes of the cross-flow filters with stainless steel membranes). It allows for cross-flow filtration of difficult to treat products with concentration up to 95% V/V on the outlet.

Very good results have been achieved with fruit juices and the technology is also ideal for the treatment of ‘’tank bottoms’’. Equipped with stainless steel membranes adapted to handle materials susceptible to clogging, the membranes have the characteristics to be long lasting and resistant to pressure, temperature and chemicals. Tank bottoms are filtered through a series of 2 to 8 membranes of 7.5 m² each. The filter is entirely automatic and only requires monitoring. The Lees -Stop effectively free users from the daily use of rotary drum vacuum filters. The filtrate is perfectly clear (< 1 NTU) and can directly be added into the filtered batch without undergoing any additional treatment. Filtration is more productive than with a rotary drum vacuum filter as it will not cause loss of quality (or alcohol) and provides better recovery rates. Residues still containing alcohol can easily be vaporized during distillation.